Introduction

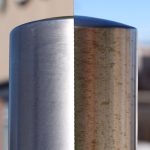

To have their optimum corrosion resistance, stainless steel surfaces must be clean and have an adequate supply of oxygen to maintain their passive surface layer.

Rust staining can occur and has been reported as anything from a slight brown ‘bloom’ on the surface to severe surface pitting or rusty scour marks on items such as handrails. These effects are usually due to surface contamination from contact with non-stainless steel items.

Iron contamination can be costly to remedy, and is avoidable.

These issues have been well documented and most publications on stainless steels deal with the problem.

Key issues to consider

Avoid contamination during all storage, handling and fabrication stages and also during the service life of the stainless steel item.

If contamination is suspected then test the surface.

Where contamination is detected take steps to remove it all and avoid spreading it around during the removal operation.

Avoiding ‘iron’ contamination

Stainless steel supplied by reputable manufacturers, stockholders or fabricators will normally be clean and contamination free.

These items should not show rust staining, unless contamination is introduced.

The use of non-stainless steel processing and handling equipment is a frequent source of contamination. Work table bearers, lifting ‘dogs’ and chain marks have all been noted as causes. Non-metallic contact materials and vacuum lifting equipment should be used to avoid process contamination.

Handling or fabricating stainless steel on equipment, using tools also used for non-stainless steels should be avoided. Working in ‘mixed-metal’ fabrication shops, without taking segregation and cleaning precautions can result in contamination.

Cutting or grinding debris from non-stainless steels should not be allowed to settle on stainless steel items.

As soon as any of this contamination becomes wet, rust staining will result.

Testing for ‘iron’ contamination

American standards ASTM A380 and A967 outline iron contamination tests.

Some of the tests simply look for rust stains from contact with water or high humidity environments, but for detection of the ’cause’, i.e. free iron on the surface, rather than the ‘effect’, which is the resulting rust stains, then the ‘ferroxyl test’ is probably the better method. This will detect either free iron or iron oxide and is sensitive enough to detect small levels of contamination.

ASTM A380 outlines the procedure in section 7.3.4.

Nitric acid is added to distilled water, followed by the potassium ferricyanide.

The ‘recipe’ is shown in the table.

| Distilled water | 94 weight % | 1000 cm3 |

| Nitric acid | 3 weight % | 20 cm3 |

| Potassium ferricyanide | 3 weight % | 30 grams |

Preparation of the solution must be done using equipment where no iron or steel comes into contact with the reagents. It should be applied to the stainless steel surface preferably using an atomiser spray.

A blue stain, appearing in about 15 seconds, indicates the presence of iron. The solution has to be removed from the surface as quickly as possible after testing using either water or 5-20% acetic acid (or vinegar) and scrubbing with a fibre brush, finally rinsing with the solution used, several times.

The standard notes that potassium ferricyanide is not toxic, but that the fumes may become toxic if the solution is heated, or if it comes into contact with concentrated acid.

Test kits are available commercially from some BSSA member companies.

Removing ‘iron’ contamination

Any cleaning process that can remove embedded iron can be used.

It is important to ensure that all the contamination is removed or not spread to other areas of the stainless steel product surfaces, otherwise rust staining can recur. In this respect, chemical, rather than abrasive cleaning may be advisable.

Cleaning and iron recontamination is well documented in stainless steel cleaning product suppliers literature and literature published by the Nickel Development Institute.

As with cleaning, a stepwise approach, depending on the severity of the staining should be considered.

Nitric acid or nitric / hydrofluoric acid preparations are the most effective but may cause surface etching, which may be unacceptable on the restored item.

Methods for removing ‘iron’ contamination

Mild staining or surface ‘bloom’

Mild-non scratching domestic cleaning creams or polishes can be used.

These usually contain calcium carbonate, with surfactant additions. ‘Jif’ kitchen cream cleaner (Lever Brothers Ltd) is an example of such a product.

Domestic stainless steel cleaners, which may contain citric acid can also be used. Shiny Sinks -(Home Products Ltd) is an example of such a product.

Fresh iron / steel grinding grit or dust

A saturated solution of oxalic acid, applied with a soft cloth or cotton wool and allowed to stand for a few minutes, without rubbing or abrading.

This should etch out the iron particles, without leaving scratches or significantly altering the surface texture of the stainless steel.

Moderate rust staining

Phosphoric acid cleaners can be effective if sufficient time and care is taken, with minimal risk of etching the surface.

Alternatively, dilute nitric acid should remove small amounts of embedded iron and will help repassivate the cleaned surface.

More severe rust staining

Nitric / hydrofluoric acid pickling preparations should remove more embedded iron than nitric acid alone.

Surface etching is likely and so complete restoration to the original finish and surface texture may not be possible.

If these preparations are left on stainless steel surface too long, pitting can be caused.

There is a limit to what can be achieved. Although contamination may be removed, these treatments will not remove any pitting associated with severe staining. In such cases mechanical grinding may have to be considered to ‘bottom-out’ the pits which means that a complete restoration of the surface will then be needed.

Cleaning methods for stainless steel

Stainless steel is easy to clean. Washing with soap or mild detergent and warm water followed by a clear water rinse is usually quite adequate for domestic and architectural equipment. Where stainless steel has become extremely dirty with signs of surface discolouration, (perhaps following periods of neglect, or misuse), alternative methods of cleaning can be used, as outlined below.

| Requirement | Suggested Method 1,2 | Comments |

|---|---|---|

| Routine cleaning of light soiling | Soap, detergent or dilute (1%) ammonia solution in warm clean water. Apply with a clean sponge, soft cloth or soft-fibre brush then rinse in clean water and dry6 | Satisfactory on most surfaces |

| Fingerprints | Detergent and warm water, alternatively, hydrocarbon solvent | Proprietary spray-applied polishes available to clean and minimise remarking |

| Oil and grease marks | Hydrocarbon solvents (methylated spirit, isopropyl alcohol or acetone) 2 | Alkaline formulations are also available with surfactant additions e.g.’D7′ Polish1 |

| Stubborn spots, stains and light discolouration. Water marking. Light rust staining | Mild, non-scratching creams and polishes. Apply with soft cloth or soft sponge and rinse off residues with clean water and dry6,7. | Avoid cleaning pastes with abrasive additions3. Suitable cream cleansers are available with soft calcium carbonate additions, e.g. ‘Jif’, or with the addition of citric acid, e.g. Shiny Sinks1. Do not use chloride solutions8,9. |

| Localised rust stains caused by carbon steel contamination | Proprietary gels, or 10% phosphoric acid solution (followed by ammonia and water rinses), or oxalic acid solution (followed by water rinse).6 | Small areas may be treated with a rubbing block comprising fine abrasive in a hard rubber or plastic filler. Carbon steel wool should not be used, nor should pads that have previously been used on carbon steel. A test should be carried out to ensure that the original surface finish is not damaged. |

| Burnt on food or carbon deposits | Pre-soak in hot water with detergent or ammonia solution. Remove deposits with nylon brush and fine scouring powder if necessary. Repeat if necessary and finish with ‘routine cleaning’. | Abrasive souring powder can leave scratch marks on polished surfaces. |

| Tannin (tea) stains and oily deposits in coffee urns | Tannin stains – soak in a hot solution of washing soda i.e. sodium carbonate. Coffee deposits – soak in a hot solution of baking soda (sodium bicarbonate). | These solutions can also be applied with a soft cloth or sponge. Rinse with clean water. Satisfactory on most surfaces. |

| Adherent hard water scales and mortar/cement splashes | 10-15 volume % solution of phosphoric acid. Use warm, neutralise with dilute ammonia solution, rinse with clean water and dry6. Alternatively soak in a 25% vinegar solution and use a nylon brush to remove deposits. | Proprietary formulations available with surfactant additions. Take special care when using hydrochloric acid based mortar removers 8,9. |

| Heating or heavy discolouration | a) Non-scratching cream or polish e.g. Solvol Auto Chrome Metal Polish 1,9

b) Nylon-type pad, e.g. ‘Scotchbrite’ 3,4,5 |

a)Creams are suitable for most finishes, but only use ‘Solvol’ on bright polished surfaces. Some slight scratching can be left.

b)Use on brushed and polished finishes along the grain. |

| Badly neglected surfaces with accumulated grime deposits | A fine, abrasive paste as used for car body refinishing, e.g. ‘T-cut’ rinsed clean to remove all paste material and dried1. | May brighten dull finishes. To avoid a patchy appearance, the whole surface may need to be treated. |

| Paint, graffiti | Proprietary alkaline or solvent paint strippers, depending upon paint type. Use soft nylon or bristle brush on patterned surfaces. | Apply as directed by manufacturer. |

| Notes

1. The products referenced in this information sheet are understood to be suitable for stainless steels. However, no endorsement of the products or their manufacturers is implied and it is acknowledged that other manufacturing companies may provide products of equal or better quality. The following companies manufacture proprietary names mentioned: – ‘Jif’ – Lever Brothers Ltd, ‘Shiny Sinks’ – Home Products Ltd, ‘Ajax’ – Colgate Palmolive Ltd, ‘D7 Stainless Steel Polish’ – Diversey Ltd, ‘T-Cut’ – Automotive Chemicals Ltd and ‘Solvol Auto Chrome Metal Polish’ – Hammerite Products Ltd 2. Cleaning agents should be approved for use under the relevant national environmental regulations and, in addition, prepared and used in accordance with the manufacturers or suppliers’ health & safety instructions. Solvents should not be used in enclosed areas. 3. Nylon abrasive pads should be adequate for dealing with most deposits. If a more severe treatment is needed to mask coarse scratches or physical damage on a surface, use the finest abrasive medium consistent with covering the damage marks. With directional brushed and polished finishes, align and blend the new “scratch pattern” with the original finish, checking that the resulting finish is aesthetically acceptable. Silicon carbide media may be used, especially for the final stages of finishing. Avoid using hard objects such as knife blades and certain abrasive/souring agents as it is possible to introduce surface scuffs and scratches. Scratching is particularly noticeable on sink drainer areas. These are usually superficial and can be removed with proprietary stainless steel cleaners or, alternatively, with a car paint restorer, such as ‘T-cut’. 4. If wire brushes are used, these should be made of a similar or better grade of stainless steel. Ensure that all abrasive media used are free from sources of contamination, especially iron and chlorides. 5. When cleaning a surface with any chemical preparation or abrasive medium, a trial should be done on a small, unobtrusive hidden or non-critical area of the surface, to check that the resulting finish matches with the original. 6. To avoid water marks, use clean rinsing water, such as reasonable quality potable (tap) water. Drying marks may be avoided using an air blower or wiping with clean disposable wipes. 7. Rust marks or staining on stainless steels is unlikely to be the result of corrosion to the stainless steel itself (similar marks may also be found on porcelain and plastic sinks). These marks are likely to result from small particles of carbon steel from wire wool or scouring pads becoming attached or embedded in the surface. In the damp environment of a sink, these iron particles rust and cause staining. Rust marks may be removed using non-scratching creams or alternatively using an oxalic acid solution, where iron particles have been embedded in the surface. Special precautions are necessary with oxalic acid, as, although it may not “burn” unprotected skin, it is poisonous, if ingested. 8. Chloride-containing solutions, including hydrochloric acid-based cleaning agents and hypochlorite bleaches can cause unacceptable surface staining and pitting, and should not be used in contact with stainless steels. Under no circumstances should concentrated bleaches contact decorative stainless steel surfaces. Hydrochloric acid based solutions, such as silver cleaners, or building mortar removal solutions must not be used in contact with stainless steels. Hypochlorite containing bleaches must be used in the dilutions suggested in the manufacturers’ instructions and contact times kept to a minimum. Thorough rinsing after use is very important. A frequent cause of staining and micropitting of stainless steels is splashing with undiluted bleach solutions and mortar cleaners. Soaking stainless steel sinks or cookware in dilute bleach solutions for long periods e.g. overnight is not advisable. Similarly, common salt added during cooking or concentrated salt/vinegar mixtures may cause pitting over a period of time. It is good practice to wash stainless steel surfaces after food preparation and cooking. 9. Heavy heat tinting (oxidation) of stainless steel surfaces is unlikely to be encountered in normal use. Normally repeated cleaning with non-scratching creams should remove burn marks from stainless steel cookware, but in exceptional cases, (e.g. after a repair requiring welding or after fire damage) it may be necessary to clean these areas using nitric acid-hydrofluoric acid pickling pastes or a nitric acid passivation solution. Changes in surface appearance usually result when cleaning with these acids. Strong acids should only be used for on-site cleaning when all other methods have been proved unsatisfactory. Nitric and phosphoric acids can be used with care for cleaning and maintenance on stainless steels, but sulphuric and hydrochloric acids can be very corrosive and should not be used for cleaning and maintenance of stainless steel items. Citric acid cleaners are less potentially hazardous. Rubber gloves should be used when handling strong acids and care taken to avoid spillage over adjacent areas (see note 2). 10. If all the suggestions and actions in the table have been attempted unsuccessfully, it is worth bearing in mind that stainless steel can be mechanically polished or electropolished by specialists on site. Stainless steel is homogenous and does not rely on surface plating or its corrosion resistance. If in difficulty contact your supplier or the BSSA References Before commencing any task ensure that you have received the appropriate health and safety literature from the supplier and fully understand it. If in doubt seek advice. |

||

Source: BSSA